CALL US TODAY · 203-214-2135

TPO Roofing Service in Connecticut

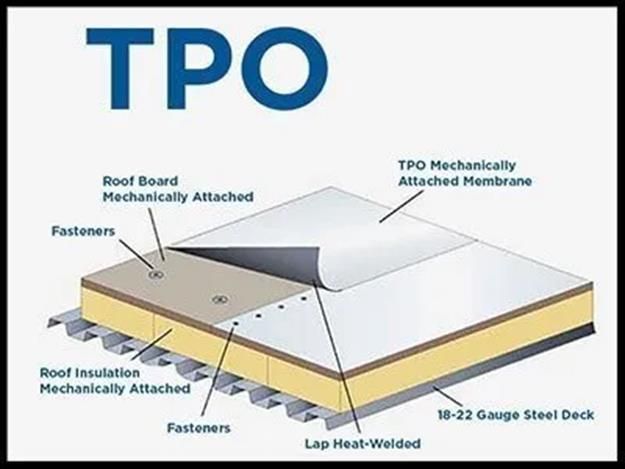

TPO, which stands for Thermoplastic Polyolefin is possibly the fastest growing

commercial roofing system on the market. It is made up of a single layer of synthetics

and reinforcing scrim that can be used to cover flat and semi-flat roofs. The name is a bit misleading, because rather than being plastic, TPO is one of a few different types of rubber, usually a blend of polypropylene and ethylene-propylene rubber.

The main advantage of TPO is that it is typically the lowest material cost for single ply membrane roofs, costing as low as EPDM and other types of rolled rubber roofing. The next advantage to point out is the color. TPO typically comes in white on top, which can help reflect the sun’s light and stop heat buildup within the building.

Other positives to TPO membrane are that it offers choices as to how it can be installed. It can be attached with adhesives or fastened directly to the roof deck. It can also be heat welded in places around chimneys and other protrusions.

Finally, TPO resists corrosion and breaks down upon contact with numerous materials. It also does not promote mildew or algae growth and does not require pressure washing. Because of these traits, it makes the material even easier to care for during the annual checkup.

Get a Quote

Contact Us

We will get back to you as soon as possible.

Please try again later.

Pros & Cons of TPO

Pros

- Provides outstanding resistance to ozone, ultraviolet rays, and some chemical exposure at a low cost.

- Reflects heat radiation – better than EPDM.

- Resists mold growth, dirt accumulation, tears impacts and punctures.

Cons

- Heat welding the seams requires a very high-quality installation to hold up over time.

- Some formulations of the material may not last much past the 10-year mark.

- Newer technology makes for a lack of a proven track record.

Location

14 Valleybrook Rd, West Haven, Connecticut

06516

Business Hours

- Mon - Sun

- -